Services

At Asset Peak Performance we believe that every job can be broken down to small pieces of to do tasks and the First thing to do is to go down to earth, list your assets, categorize them, and determine the type of maintenance practices suitable to be applied for each category.

Based on our experience we have listed the Maintenance practices used by the different industries and then we show our services and added value.

A. Maintenance Practices

B. Vibration Analysis

C. Bearing Failure Analysis

D. Bearing Mounting and Dismounting

E. Bearing Lubrication Management

F. Laser Alignment

G. Field and Workshop Dynamic Balancing

A. Maintenance Practices

I. Breakdown maintenance

• Definition:

You fix the machine when it breaks.

You fix the machine when it breaks.

• Results:

a) Downtime is common

b) Secondary damages are COSTLY

c) Control is lost over production

II. Preventive maintenance

• Definition:

You perform regular

overhauls based on a scheduled time so that the machine will not fail.

You perform regular

overhauls based on a scheduled time so that the machine will not fail.

• Results:

a) LESS COSTLY than breakdown maintenance

b) Repair intervention is based on time

c) Many times you fall into the breakdown maintenance because you are basing your practices on time and not on operating conditions of the machine.

III. Predictive maintenance

• Definition:

You don’t fix it if it will not breakdown.

• Results:

a) MUCH CHEAPER than preventive maintenance

b) Repair intervention is based on operating conditions

c)

This is the only way to look

into the future since machines express their pain before failing. Their problems

have symptoms. Many technologies help us interpret these symptoms to understand

their causes. We can rely on:

This is the only way to look

into the future since machines express their pain before failing. Their problems

have symptoms. Many technologies help us interpret these symptoms to understand

their causes. We can rely on:

o Vibration analysis

o Oil analysis

o Thermal imaging

o Motor current analysis

o Ultrasound

IV. Proactive maintenance

• Definition

You need to anticipate and solve the problems even before they occur.

• Results:

a) THIS IS THE ONLY WAY TO EXTEND THE LIFETIME OF THE MACHINE

b) After checking symptoms using predictive maintenance, we perform root cause analysis to treat and solve the cause.

c)

Experts should go through

details like the following few points:

Experts should go through

details like the following few points:

o Purchase specifications

o Installation procedure, levelling, precision alignment, …

o Acceptance testing

o Routine maintenance procedure, tools,…

o Condition monitoring technologies

d) LOWEST COST

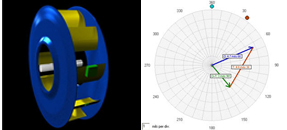

B. Vibration

Analysis

I. Advantages:

1. Determine the severity of the problem if it exists

2. Determine the source of the problem

3. Determine the type of the problem

4. Determine the way for solving the problem

5. Determine the remaining lifetime of the machine before breakdown

II.

Applications:

Applications:

1. Electric motors

2. Pumps

3. Fans

4. Gearboxes

5. Turbines

6. Compressors

7. Engines

8. All rotating components

III. Return On Investment Calculations to show savings from:

1. Mechanical components cost

2. Secondary damages

3. Energy consumption

4. Unexpected production stoppage

5. Labor cost

We take the right actions at the right time to avoid these costs.

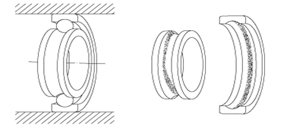

C. Bearing Failure Analysis

The bearing is subject to all loads generated from the machine, the process, induced vibration from the surrounding …

Our experience leads us to identify patterns which can tell us the root cause of

the failure.

I.

Every type of problems has its

own unique signature that help us know if this is:

Every type of problems has its

own unique signature that help us know if this is:

1. Misalignment

2. Eccentricity

3. Unbalance

4. Type of lubrication

5. Ingress of contamination

6. Current fluting

Above problems can be treated to avoid their re-occurrence.

D. Bearing Mounting and Dismounting

I. We prepare a file specific for each equipment for mounting and dismounting bearings procedure.

Fail to plan is plan to fail; we plan our activities and conceive procedures for evaluation.

E. Bearing

Lubrication Management

E. Bearing

Lubrication Management

I. Studies

SKF studies showed that:

- 36% of bearings fail due to bad lubrication

- 14% of bearings fail due to contamination

This is 50% of bearing failure causes

II. Factors leading to successful lubrication:

- Right type of lubricant for the application

- Lubricant quantity

- Re-lubrication Intervals

- Re-lubrication procedure

- Lubricant performance monitoring

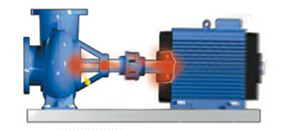

F. Laser Alignment

F. Laser Alignment

I. Applications:

1. Horizontal shaft alignment

2. Vertical shaft alignment

3. Soft foot

4. Thermal growth compensation

5. Cardan shaft

6. Machine train

7. Belt and chain drive

8. Straightness

9. Flatness

10. Squareness

11. Parallelism

12. Spindle alignment

II. Typical problems arising from misalignment are:

1. Lost production

2. Leaking seals

3.

Increased vibration

Increased vibration

4. Higher energy consumption

5. Bearing failure in less than one year

6. Shaft breakage

7. Coupling wear

8. Quality problems

9. Labor cost

Read the Study and ROI made on One Electric Motor after Alignment

G. Field and Workshop Dynamic Balancing

Machines that have been precision balanced run longer and cost less to run

I. Unbalance Facts:

1.

Unbalance causes fatigue and

reduces the life of bearings.

Unbalance causes fatigue and

reduces the life of bearings.

2. Unbalance can make looseness and resonance conditions far worse.

3. Unbalanced rotors generate destructive vibration to machinery components leading to:

o Unavoidable breakdown

o Damaged machinery structure

o Damaged mechanical components

o Excessive additional energy consumption

o Production stoppage